Your favorite trainer is flawed. Sure, it roughly fits the length and width of your foot, but it probably doesn’t accommodate your unique stride or long middle toe. To address this, manufacturers are embracing technologies that allow them to make personalized design changes with just a few keystrokes.

In the past six months, two companies— and —began printing insoles based on smartphone photos uploaded by customers (cost: $99 and up). But it’s the technology used by big brands like Adidas, Brooks, and Nike that could revolutionize athletic footwear.

“We’re going to see a high level of customization,” says Katherine Petrecca, who heads up New Balance’s innovation studio. “It’s in beta now, but we may have a consumer shoe within the next three years.” When bespoke trainers arrive, these are the methods that will make them the finest you’ve ever laced up.

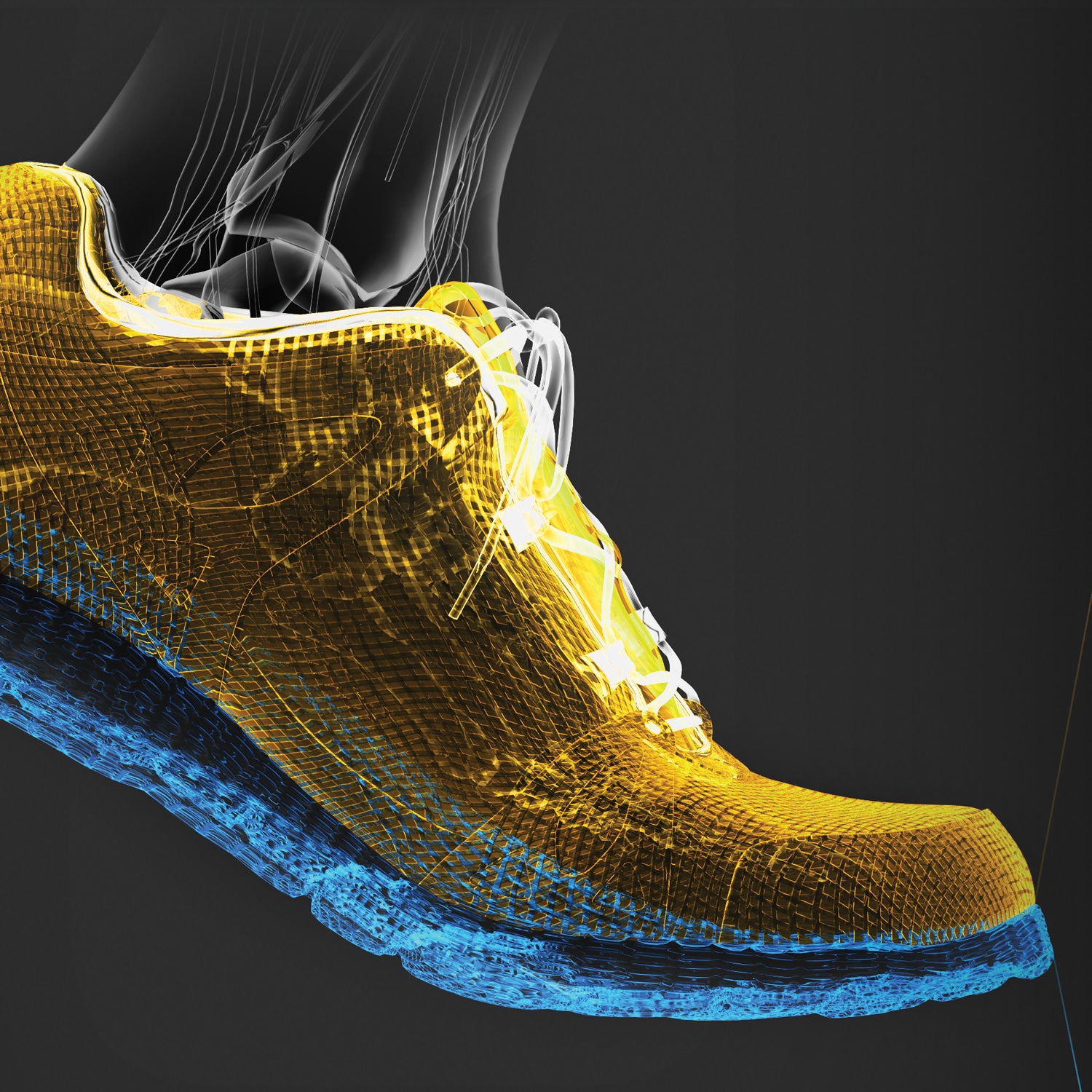

Selective Laser Sintering

How It Works: A 3-D printer uses heat from a laser to fuse powdered plastic into a finely detailed solid. The process allows for unprecedented control over shape and density, creating a “copy of the athlete’s footprint,” says Paul Gaudio, global creative director at Adidas.

Who Will Use It: Adidas, New Balance, Nike, Under Armour

Laser Siping

How It Works: By cutting precision grooves into a traditionally molded sole, designers can create the perfect ride, altering flexibility, cushioning, and support anywhere a runner wants. “Different depths and gaps create different sensations,” says Tae Lee, a design director at Nike.

Who Will Use It:���������

�侱�����ܱ����������Ծ��ٳپ��Բ�

How It Works: A computer-controlled machine creates custom shapes and zones in a shoe’s upper that provide extra support or flex where a runner needs it. Nike uses the process in its Flyknit models and has hinted at the possibility of customization.

Who Will Use It: Adidas, ASICS, Brooks, Nike, Pearl Izumi