I could give you the spiel about my love of the vanlife conceptÔÇöIÔÇÖve wanted to do it since before Instagram was a thing, IÔÇÖm a╠řcamping nerd, I think travel is good for a healthy economyÔÇöbut IÔÇÖll get straight to the point: I donÔÇÖt think people should build out a vehicle for a price tag that has more than two zeros before the decimal.╠ř

Instead, like any twentysomething╠řwith a low-to-average paycheck, I looked at what I already hadÔÇöa 2008 Subaru ForesterÔÇöand thought, ÔÇśI bet I could make a cheap build in the back of that.ÔÇÖ So I called up Larry Dube, my dad and a software engineer with a knack for woodworking, and hatched a plan. HereÔÇÖs what we came up with.╠ř

The Requirements: I didnÔÇÖt want to remove my back seats╠ř(what if I had to drive my friends somewhere?), needed╠řenough room for my 40-pound dog and I to curl up and sleep, and had to have╠řplenty of storage. But most of all, I wanted to experiment with a design that╠řvirtually anyone could do regardless of their skill level, all for less than $350, which seemed to be about as cheap as I could get╠řfor our design.

The Caveats: I had access to the tools from my dadÔÇÖs workshop, which heÔÇÖs been filling for decades. Having him around for the project╠řwas a huge asset, because he has a building brain.╠ř(ItÔÇÖs a thing!) And because of him, I know my way around a workshopÔÇöa very╠řhelpful starting point.╠ř

For anyone lacking╠řaccess to tools, fear not: depending on your location, you can rent them at places like ╠řand╠ř. If you prefer to╠řown stuff, you can rent-to-own the necessities╠řat ╠řor get discounted used tools at Home Depot, Craigslist, and╠ř.╠řFor the purposes of this article, IÔÇÖll be pricing out tool rentals╠řfrom Home Depot.╠ř

If youÔÇÖre new to╠řwoodworking, there are tons of resources available to get you rolling. Check out Instagram and YouTube for pointers and basic instruction. My dad and I turned to╠ř╠řand got a lot of inspiration from its designs.

The Timeline: We completed╠řthis build over the course of about eight days, working in the time after our nine-to-fives╠řand on the weekends for a rough total of 40 hours.

This design╠řis in no way prescriptive of what you should do for your own Forester,╠řother Subaru models, or any other vehicle that you already have. IÔÇÖm splitting it up into╠řparts so you can decide where you want to stop or improvise. (DonÔÇÖt want a cabinet but do want drawers somewhere? Raise your sleeping╠řplatform a few inches and utilize that space. Just interested in╠řa bare-bones platform? Ignore the add-ons.) There are countless creative builds out there to draw inspiration╠řfrom.╠ř

Pro Tips and Things to Consider

- Having a plan╠řbefore╠řyou╠řstart, right down to the hardware and specs, will make the build-out that much easier. My dad and I went back to the drawing board multiple times, even with initial specifics nailed down.╠ř

- We used the mud mat that came with the car to speed up the build process╠řby tracing its outline on our plywood. That╠řmade it super easy to cut out the funky design we needed for the back half of the sleeping platform.╠ř

- Measure everything,╠řthen measure it again. While youÔÇÖre doing so, be╠řsure to account for the width of your plywoodÔÇöhalf-inch or three-quarter-inch plywood adds╠řup╠řfast.╠ř

- Cut your lines as straight as possible. Even a slight curve in the wood can make things like hinges or drawers impossible to close or lay flat. Sanding down anything curvy can help in a pinchÔÇöbut itÔÇÖs also a pain in the ass.

- Make sure your car is on level ground while youÔÇÖre working on it. This becomes important when youÔÇÖre trying to get that╠řplatform just right. (YouÔÇÖll thank me when youÔÇÖre not sleeping at an angle.)

- This should go without saying, but remove all of the car tools underneath your SubaruÔÇÖs floor storage. IÔÇÖm pretty sure that my carÔÇÖs jack is now permanently built in to my Forester.╠ř

- We found that, in our area, Home Depot was generally cheaper than LoweÔÇÖs. (No, this isnÔÇÖt an ad for Home Depot or Subaru.)

Step One: Empty Out Your Car and Put in Your Base

Materials:╠ř

- One full sheet of half-inch sanded plywood

- Jigsaw

Even without removing its╠řseats, Subaru Foresters (and its╠řsisters, the Outback, Legacy, and Crosstrek) have╠řa ton of secret storage; aside from the spare tire well, there are pockets on either side in the way back, tool-storage areas under panels behind the╠řback seats, and lots of space where passengers would normally rest their legs.╠řThe well where your spare tire lives is perfect for a small battery or nonessential gear. For our build, we cleaned out the back, attached the spare to the roof with bungee cords, laid╠řthe seats down, removed all of the additional car tools hiding beneath storage flapsÔÇöexcept for that aforementioned jack, oops!ÔÇöand measured everything out.╠ř

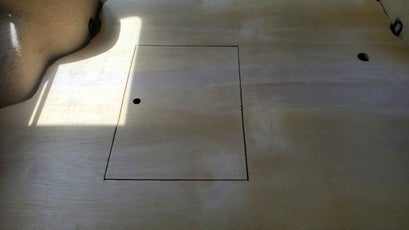

For our design, the sleeping platform had╠řthree sections: the base, the top, and a╠řremovable flap that would go over the folded-down back seats. Lay your base firstÔÇöwe used half-inch sanded plywood, cut to fit with a jigsaw. This will serve as a sort of anchor. Some builds screw this platform into the frame of the car. We didnÔÇÖt, and in our testing, it has╠řproven╠řcompletely sturdy. If youÔÇÖre╠řusing that spare well as extra storage, donÔÇÖt forget to cut a hole in the base that will allow you to access it.

Pro Tip:╠řIf you have no mud mat, lay down parchment paper or cardboard where the mud mat would have been, and trace its permeter. For beginners, this is an easier way to get a really tight fit, rather than measuring all of those odd╠řangles. YouÔÇÖll want to use this strategy again, in step two,╠řto trace the top of the platform.╠ř

Step Two: Raise Your Sleeping Platform

Materials:╠ř

- One full sheet of╠řthree-quarter-inch sanded plywood

- One eight-foot-long two-by-four

- One eight-foot-long two-by-six╠ř

- Two chest latches╠ř

- Three 36-inch piano hinges╠ř

- Package of one-and-five-eighths wood screws

- One 12-inch piano hinge (optional)

- Jigsaw

- Circular saw╠ř

- Electric drill

Repeating the same process described in step one, retrace that mud mat on a sheet of three-quarter-inch plywoodÔÇöthis will result in the top of the platform. DonÔÇÖt forget to cut a panel╠řso you can reach your lower storage╠řfrom╠řthis top section as well (we let our panel rest on pieces of wood and just lifted it out, but you can add a hinge here based on your preferenceÔÇösee photos above).╠řTo support╠řthe╠řplatform, we used a two-by-six╠řsectioned into three parts and shaved down as needed with a table saw (a jigsaw and some good sanding can also do the trick here)╠řto make sure the entire platform would be level. Perpendicular to those two-by-sixes, we inserted╠řa two-by-four at the base of my carÔÇÖs╠řback seats to hold up the front end╠řof the top platform. This╠řtwo-by-four is key: youÔÇÖre going to want to cut the top panel so it rests at just about the halfway point of it, because the removable panel that will go over your seats needs to rest here, too.╠ř

We also used the three-quarter-inch plywood to create the removable panel that would go over the seats. We got slightly overexcited about the design here without thinking about how clunky it might be to take out, so definitely riff on our idea. The platform we came up with consists╠řof four parts: two rectangles in the middle and two flaps on either side to accommodate for the space near the doors. We attached these parts╠řtogether with piano hinges, so the╠řentire piece folds up like an accordion for removal and storage╠ř(see the╠řabove photos). When flat, the panel╠řlays on the lip of that aforementioned two-by-four, and once it was all╠řfastened in, we attached the two halves of the sleeping platform together with a couple of chest latches.╠ř

Once everything is╠řsaid and done, youÔÇÖll find╠řthat the╠řtwo-by-fours beneath your platform create some pretty nice storage in the corners of your car. This wasnÔÇÖt in the plan, but I also cut a section out of my sleeping platform, popped a piano hinge on it, and created another accessible storage area. In addition, we╠řpopped in a simple pull-out table on one side; itÔÇÖs╠řmade from╠řscraps of╠řplywood, with╠řtwo-by-sixes for the legs, and is attached by . Modify at will!

Pro Tip: A circular saw will help you cut straighter lines than a jigsaw. Use it anywhere where hinges are involved.╠ř

OK, before we move on to step three, which is totally optional, take a look at your carÔÇöyou now have pretty much everything you need to car camp! From here, you can decide to make the sleeping platform a few inches higher and put in some drawers, or you can take out your back seats entirely and add╠řa ton of extra storage. We opted to insert╠řcabinets because we liked staying up until 2 A.M. working on modifications. But most people are normal.╠ř

Step Three: Incorporate Cabinets and Drawers

Materials:

- One full sheet of╠řquarter-inch plywood underlayment

- A second full sheet of╠řhalf-inch sanded plywood

- Wood glue

- Package of one-inch wood screws

- One 24-inch drawer slide set

- One 12-inch drawer slide set

- Six cabinet hinges

- One folding hinge

- Three L brackets

- Circular saw

The talk of the town in the LaPlante-Dube╠řhousehold during the build process╠řwas this cabinet unit, which is sweet but relatively complicated for beginners. It was really helpful to have my dad around to make this design a reality. (This is the guy who╠řused to saw apart his sistersÔÇÖ bikes to╠řcreate a ÔÇťHarleyÔÇŁ of their combined pieces.)

We built the cabinet unit outside of the car, measuring for height as well as the thickness of the boards we would be using, and fastening╠řit onto the back half of the platform with L brackets. Disclaimer: we put it on the passenger side of the car, but IÔÇÖd recommend putting it on the driverÔÇÖs sideÔÇöthat makes it easier to see whatÔÇÖs going on in the passenger╠řblind spot. Second disclaimer:╠řwith the addition of this cabinet, your sleeping platform is only good for only╠řone person and a dog.╠ř

The cabinet unit is made of three parts: a╠řdrawer as the base and,╠řon top of it, one cabinet in the front and one in the back. To accommodate the seats coming up,╠řthe front cabinet is hinged to fold into the sleeping area (my dad added a little table platform on the back of this cabinet as a fun extra; check out the photos above). We fashioned it so the front cabinet could also pull out like a drawerÔÇöone modification possibility╠řfor people who are interested.╠ř

Pro Tip: Since this is an optional part of the build, I wonÔÇÖt get too deep into the details here. But building drawers for the first time can be╠řtricky; they require drawer boxes and tight frames, super straight lines, and patience with extremely small screws, all of which tested me. There are a ╠řon YouTube that can help you go over the simple mechanics of it.╠ř

The Build in Real Life

The scariest part about this process╠řisnÔÇÖt the sharp tools or the tiny screws or the moths flying around your late-night construction╠řsceneÔÇöitÔÇÖs making sure it all actually works.╠řSince I built out my car in July, IÔÇÖve taken it on a handful of off-road trips here in New Mexico, and IÔÇÖm happy to report that even on the bumpiest of roads, the cabinet faces stay shut, the unit hasnÔÇÖt shifted, and once IÔÇÖm╠řparked, itÔÇÖs provided╠řplenty of room for my five-foot-two-inch frame and dog.╠řStill, there are some things I would change: as previously mentioned, I would shift the cabinet unit to the other side of the vehicle, and I would definitely paint the entire build╠řin polyurethane up front: plywood stains easily and absorbs water, and having even a little protection from a muddy dog or spilled╠řcamping beer would be better than nothing.╠ř

Tool and Hardware Index

Wood:╠ř

- Two full sheets of ($74╠řtotal)

- One full sheet of╠ř ($41)

- One full sheet of underlayment ($16)

- One╠ř╠ř($4)

- One ($8)

Wood Total: $143

Hardware:╠ř

- Two packs of wood screws

- ($2.50 for 40)

- ($9.21 for 75)╠ř

- ($4)

- Two ($8 total)

- Three ($12 each)╠ř

- Two ($7 each)

- Three ($3.19 each)

- Six ($1 each)

- Three ($2.75 each)

- One ($30 for two pairs)

- One ($13.49)

Hardware Total: $141.02

Tools:╠ř

- Jigsaw (rental: )

- Electric drill (rental: )╠ř

- Circular saw (rental:╠ř)

- ($4 and up)

- ($4.29)

Tool Total: $69.29