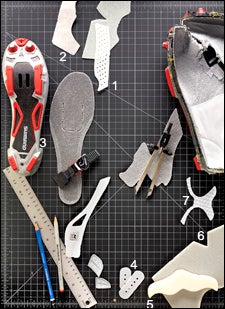

1. FIT

Mountain Bike Shoe

To pull every watt of power out of your legs, your shoe needs to fit perfectly (slop = wasted energy). Four plastic pieces like this one (at the heel, instep, arch, and little toe) are heat-molded to your foot at the bike shop for a custom fit.

2. DURABILITY

It looks like a piece of your lunch bag, but this is actually a thin strip of fiberglass that maintains the shape of the heel. Unlike pre-formed heel cups, the fiberglass doesn’t stretch outthe main reason most shoes need replacement.

3. WEIGHT

The carbon-fiber outsole reduces weight over typical nylon outsoles by up to 25 percent, while stiffening the shoe for greater power. The drawback? The material is also twice the cost: about $152 per pair.

4. COMFORT

Most shoe tongues are just floppy fabric. These Band-Aid-like strips of PVC plastic give the M310’s tongue an arch that matches the shape of your foot, adding both comfort and a touch of power-enhancing rigidity.

5. CUSHION

Party mustache? Nope. This piece of high-density foam in the heel conforms to foot contours for a blister-free fit, but springs back to its original shape afterwards, losing only5 percent of its puff over the life of the shoe.

6. EFFICIENCY

The number-one way you lose power? Heel slip. This tacky, metal-infused polyester, placed at the back of the shoe, is textured like a cat’s tonguesmooth in one direction, grippy in the otherand helps lock your foot in place.

7. INSULATION

A wishbone-shaped piece of mesh wraps the pieces of thermomoldable plastic in the heel to keep the foam from being scorched by the 200-degree temperatures it will be subjected to during a custom fitting.