FIFTEEN FEET UNDERGROUND, in a cluttered basement laboratory, Marianne Okal is systematically torturing carabiners to death. An unassuming 22-year-old senior at the Massachusetts Institute of Technology, she wears a gray zip-front hoodie, Carhartt painter’s pants, and clear plastic safety goggles. She has shiny brown eyes, short brown hair, and a reassuring smile, but don’t be fooled: She’s killed before, and she’ll kill again.

Brawn and brainiacs: CSI phenom Jennifer Blundo toys with gravity in an MIT classroom

Brawn and brainiacs: CSI phenom Jennifer Blundo toys with gravity in an MIT classroom CSI Chief Kim Blair—with the Mavic Cosmic Wheel—braves the Wright Brothers Wind Tunnel.

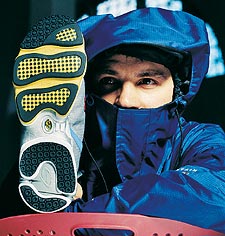

CSI Chief Kim Blair—with the Mavic Cosmic Wheel—braves the Wright Brothers Wind Tunnel. Sole Patrol: would-be sneaker reinventor Abel Hastings eyes the New Balance Triathlon Shoe.

Sole Patrol: would-be sneaker reinventor Abel Hastings eyes the New Balance Triathlon Shoe.

Mercilessly, Okal places one more helpless Black Diamond Light D carabiner in the vise grip of the MTS Tensile Loading Machine. The MTS is a hydraulic monster-gizmo that looks like two huge drill bits pointed at each other. Applying up to 100,000 pounds of pressure, the machine smashes or yanks objects apart. At the moment, Okal has it calibrated to simulate the force the carabiner would absorb if someone weighing 200 pounds fell ten feet while on a rope threaded through it—over and over again for hours, 3,608 “falls” in all, until, with a sad and final bplink!, it fractures in two.

Okal dumps a box of busted carabiners on a table. It’s an eerie sight, like the remains of a crushed bag of silver pretzels. Remarkably, they’re all broken in the same place, at the top or bottom elbow of the D. Carabiners don’t show signs of fatigue until they break, and when they go, they go completely—no slow unfurling like in Vertical Limit. Engineers call this “catastrophic failure.” Wouldn’t it be great, thought Okal and her lab partner, Jon Graham, if there were some kind of indicator to alert you that a carabiner should be retired to chalk-bag duty, well in advance of disaster?

“Our first thought was, the ‘biners must distort a little as they get pulled on over time,” Okal says. “If they did, we could put a little gauge where the spring gate fits into the side of the ‘biner, and as the ‘biner stretched, the more the gate would creep down the gauge.”

She shrugs. “But that didn’t work. They do deform, but never so you can see it.”

Okal and Graham’s next thought was to paint the elbows with something that would reveal the crack, but they quickly ruled this out; whatever they painted on would wear off during regular use. Only after busting 40 carabiners did an alternative solution occur to them: a plastic mold that carabiners could be placed in as a test. If the ‘biner doesn’t fit perfectly in the mold, that could indicate that its shape has been altered by heavy use or that an invisible crack may exist.

“We don’t know if it’ll work yet,” Okal says. “But we will soon.”

IT’S NOT QUITE the Manhattan Project—they’re splitting carabiners, not atoms—but Okal and Graham’s experiment is one of about half a dozen or so currently being explored at the MIT Center for Sports Innovation, an independent, nonprofit, multidisciplinary skunk works that promises to generate some serious light—and heat—for the $18 billion outdoor and sports equipment biz.

CSI was launched quietly in August 1999 with the goal, according to its mission statement, of developing “new technology and products which enhance all aspects of the sporting experience. The idea is to link the expertise of MIT faculty, the passion of MIT students, and the experience and insight of corporate sponsors to create a dynamic environment for product development education with a clear focus on end-use applications.” Which is another way of saying, now that the space race is over, CSI is there to make sure MIT’s aeronautical and astronautical—or “aero-astro”—engineering students can get jobs when they graduate.

Here’s how it works: Sports gear and apparel companies provide donations (in money, equipment, or both) iRn exchange for specific research or product testing. In the process, they gain access to sophisticated facilities like the Technology Lab for Advanced Composites (Okal’s torture chamber) and CSI’s Wright Brothers Wind Tunnel. Thus CSI gives companies that don’t have the cash flow of Nike—which in 1996 built its own $1.5 million, 12,500-square-foot, 25-person-strong Nike Sports Research Lab in Beaverton, Oregon—the opportunity to complement their R&D efforts without having to construct labs that might turn out to be money pits.

At present, CSI has a modest annual operating budget of $100,000 and negotiates fees paid by corporate sponsors on a case-by-case basis—$15,000 minimum for an undergraduate research project, $30,000 for a graduate project—making it affordable even for bootstrapping entrepreneurs. Unlike other schools that only test products, CSI puts the imaginations of MIT’s wunderkinder to work for its sponsors—upward of 20 undergraduate and graduate students each term, whose “job” is to solve problems and come up with innovations. As a fringe benefit, corporate sponsors get to tap into MIT’s tenured big brains in engineering and physics, as well as black arts like management science, human cognition, and niche marketing. For its trouble, MIT gets cash for the research as well as bragging rights and patents to whatever CSI’s students create.

Great as this sounds—everybody wins!—it’s still a heck of a lot to pull off. To manage it all, MIT has hired an army of one: Kim Blair. Born and raised in Grand Island, Nebraska, Blair, 43, is a certified gearhead. He completed his master’s thesis on the “fatigue behavior” of aluminum alloys—the metal used in carabiners—before spending three summers and two semesters, circa 1987-1990, at NASA’s Johnson Space Center in Houston. There he worked on designs for the Mars lander and the space shuttle, en route to getting a Ph.D. in aero-astro from Purdue University in 1992. He’s also a jock. A member of Team Psycho, a New England triathlete club (he’s completed 70 triathlons), he kickstarted his honeymoon by competing in Hawaii’s Ironman Triathlon. He sees CSI as “a really nice way to combine my profession and my hobby.

“One of the best perks,” he adds with a grin, “is we get to try the latest stuff.”

One day, Blair hopes, CSI will have an operating budget of $300,000, a staff of three (or hey—five!), and maybe even a building of its own, like its very rich cousin, the 17-year-old MIT Media Lab. In 2001 the Media Lab had $36 million in corporate lucre at its disposal to play around with what its promo brochure calls “digital technologies [that] enhance the ways people think, express, and communicate ideas.” If that’s ever going to happen to CSI, Blair first has to prove that his center can pay for itself. “We may be not-for-profit,” he says, “but at MIT not-for-profit means not-for-loss, too.”

Blair, who works on contract for MIT as a research engineer (he’s not a faculty member), was given three years by the university to get CSI up and running. So far he has attracted projects and funding from Trek, Lange, Mavic, and New Balance, among other gear companies, but the money has not exactly rolled in. In CSI’s first two years, Blair raised roughly $40,000 from the private sector and relied on university funds to keep his CSI students busy. This year, he’s got four new sponsorship proposals pending for graduate projects, which could bring in $120,000. If he closes those deals, he’ll break even for 2002. If not, CSI may have to go back to the shop for more fine-tuning before it wows the marketplace.

Blair is optimistic that his third year will be charmed, but he’s also trying to stay flexible. “I’ve been able to create all this on a shoestring,” he says, but “it’s still a one-person show.” He stresses that many projects, like Okal’s ‘biner breaking, are independently conceived operations; corporate sponsor or no, students get course credit for their work.

“My primary focus will always be the educational mission,” he says. “That’s what the Center does best—it gives students a great hands-on experience.” Going for the Next Big Thing “will never be the live-or-die focus.” But, he laughs, “I sure wouldn’t mind.”

THE DAY I WITNESS the ‘biner massacre, I’m also shown projects CSI is working on for Lange (calibrating settings for the Rear Release System on its V9 downhill ski boot) and Mavic (testing the aerodynamics of its Cosmic bike wheel), as well as a bevy of in-house prototypes. There’s a climber’s exercise apparatus (a wooden pyramid with edges and notches on all sides to improve balance and toe placement), a “bladder bolt” (an inflatable rubber tube to be used as protection in rock climbing), a “poop chute” (a small parachute that lets climbers dispose of their excrement while up on big walls, so as to avoid shit-bombing the climbers below), and an automatic belay device called Johnny Belay, later renamed the iClimb (a winch activated by remote control so a person can climb in a gym without a human belaying partner).

Most of these are student experiments, and as such don’t contribute any money to CSI’s kitty unless or until Blair and his charges are able to sell the idea on the open market. But I also get to inspect one of the very first New Balance M920s, special triathlon shoes with a heel-strap instead of a solid back (making it easier to slip a soggy foot into). The shoe, based in part on the work of a class of ’01 CSI student named Chi-An Wang, was sponsored by New Balance to the tune of $5,000 and is due in stores this June.

Still, for CSI, innovation is not just about inventions. “Just as often as we’re trying to make something new, we’re trying to examine conventional wisdom,” Blair points out. “Sometimes reinforcing it, other times debunking it. A lot of what we do is getting the noise out of the data.”

To wit: In 2000, when Trek came out with its latest carbon-fiber bike frame (built for the U.S. Postal Service Cycling Team that raced in the Tour de France), Blair used the wind tunnel to test the frame and to give feedback on its rider—Lance Armstrong’s former teammate, Tyler Hamilton. “We put him in the wind tunnel and we dialed his position with respect to the frame,” Blair says proudly. Translation? CSI helped Hamilton configure the bike for minimal wind resistance. That kind of data, and the manner in which it was obtained, indicates how elite athletes think about winning these days. It’s a war of incrementalism out there, and technology is the key.

“The top people in a sport are only hundredths of a second apart,” notes Gerhard Pawelka, 37, currently director of new ventures at the Boston offices of IDEO, an international design concern. He’s tested products at CSI, and thinks it’s important that MIT has tools “that can measure, and accurately measure, down to the tenths and hundredths of a percentage point. The ground for refining products has gotten thin. That makes even minute improvements count for more.”

There’s one other thing, however, that gear makers demand: testers who can take their products out of the lab and into the mud. “From a lab perspective, I’d have no misgivings about using MIT,” says Dan Levine, director of design and development for REI’s 40-person Gear & Apparel Group. “But from a field perspective, they have to have the users. I trust their white lab coats, but who’s trying on the breathable wet coats?”

Blair says he’s got this covered. He recruits his testers from a student body that’s desperate to take a break from quantum physics and go outside to play. “When I have a cycling project, I e-mail the cycling-club list,” he says. “We’ve got 5,000 undergrads and as many graduate students, and almost all of them have a sport. I’d have to say that’s really the single most important thing we offer: students who are ‘lead users.'”

His use of that term is no mistake. It comes from The Sources of Innovation, a recently reissued handbook by MIT Sloan School of Management professor Eric von Hippel. It took a tweedy business prof to convince some corporate tyros what any unhappy camper knows only too well: The person who has spent a miserable night in a leaky sleeping bag understands better than anybody what it’ll take to make it work.

IT’S 8:15 A.M. and we’re on the road to New Balance’s manufacturing facility in Lawrence, Massachusetts. Blair drives while Abel Hastings, a 29-year-old grad student in MIT’s material science program, warms up his spiel on us. Hastings has a Mr. Peabodyesque amount of knowledge crammed into his head. When he speaks about the biomechanics of running, he uses terms like “injury modality” and “gait optimization.”

“My idea is to investigate running- shoe design from the ground up, using biomechanics, physical modeling, and investigating new materials,” Hastings says. “There’s just been so much that hasn’t made its way into the industry yet.” In short, Hastings hopes New Balance will underwrite a study that could lead to reinventing the sneaker, perhaps by identifying superior impact-absorbing compounds for the soles.

Reinvent the sneaker—no biggie, right? As crazily ambitious as that sounds, Blair wants New Balance to hear Hastings out. The company has told him, he says, that if he and his whiz kids can find an alternative to EVA—the industry-standard foam used in the soles of running shoes, which gives them that cushy feel but breaks down rapidly, even when not in use—”then they’ll give us a bunch of money.”

Sitting in as Hastings makes his pitch to Edith Harmon—director of the Advanced Products Group, the running shoe giant’s in-house R&D unit—it doesn’t seem like Blair should have trouble lining up corporate sponsors. After all, the early experimental stages of product development—known in the industry as the “fuzzy front end”—can rapidly narrow a company’s profit margins. In some cases, it can cost more to produce the first prototype than to bring a product to market.

“We have an internship program and we have our own R&D,” says Harmon, “but what Kim gives us, above and beyond a way to contribute to higher education, is a cost-effective way to try out new concepts.”

The hurdle Blair has to negotiate is this: In a field as highly competitive as sports equipment and apparel, no one wants to pay for innovations that their rivals can readily poach. Various federal guidelines, as well as MIT’s own policies to retain rights to research patents created by students in the university’s labs, make some sponsors reluctant to pony up the cash needed to develop bleeding-edge technology at CSI. “It’s not just MIT,” says Blair. “And it’s not about who gets to publish the results. The industry moves so fast, the technology is in the market before anybody can really publish anything on it. So it’s a question of who owns what, when, and for how long. And we can’t always come to terms.”

Michael Blenkarn, director of product development and new technologies at Arc’Teryx, the Vancouver, British Columbia-based maker of climbing harnesses, packs, and outdoor apparel, says it would be a shame if patent lawyers kept CSI from gaining momentum. “We already have enough lawyers making a mess of things in this industry,” Blenkarn, 42, grouses half-jokingly.

He then voices a common lament of anyone over 35 in the biz. “Ever since the late 1970s, when manufacturing moved overseas, innovation has fallen off,” he says. “Because all the tents are sewn by the same four factories now, once someone tries something, everyone else can just go to the trade show, see if they like it, and order up the same thing. You’ve got a tent with one million hanging lockers? Well, I’ll make one with two million hanging lockers! It’s just more of the same.”

Paul Kramer, the 55-year-old cofounder and design director of the high-test gear company Mountain Hardwear, mostly agrees. “I think it’s possible to design something and have someone else produce it, and still be innovative,” he says. But when manufacturing moved overseas, startups in North America could no longer compete on price with stuff made in Taiwan. “When the cost of getting into something is low,” Kramer notes, “everybody can get in, and when you have all these little guys competing, that’s when you see innovation.”

“The real innovators are always the ones who live and breathe it,” adds Blenkarn, which is why CSI sounds promising to him—so long as Blair’s “lead users” never forget that the wild is the best and final laboratory.

“There was this project in the UK,” Blenkarn recalls, ending our conversation with a cautionary tale from the annals of gear development. “Some university got a big grant to build the world’s most ergonomic backpack ever. Karrimor [a British pack maker] was going to commercialize it. And when the university came out with it, why, it was gorgeous! It looked like a frame pack based on the skeletal reflection of the human body. But no one had taken it on the trail, much less thrown it in with other bags on the back of a truck or an Indian bus.” Blenkarn sighs. “Ends up, it was a real fucking expensive piece of schmoo.”

“WELL, THAT SEEMED to go well,” Blair tells Hastings as we cross the New Balance parking lot. New Balance didn’t tell him yes, but it didn’t say no. The next step will be to haggle over the $30,000 grant Hastings is looking for, and perhaps to focus his proposal.

When we get back to the lab, Blair has one more whiz kid he wants me to meet. If Blair is the Batman of CSI, then Jennifer Blundo is, for now, his Robin. A 21-year-old double major in mechanical engineering and management science, Blundo looks like your run-of-the-mill MIT student—a young woman in jeans and gray fleece, toting an overstuffed backpack that threatens to pull her over backward. But even among MIT’s elite undergrads, she’s a standout—an avid runner who has her sights set on the Boston Marathon, and who aims to get a master’s in mechanical engineering and an MBA. Last fall she co-led a team of 17 in constructing the iClimb. Talk to her for ten minutes and it’s easy to imagine her pitching some future company to investors, just as she is now selling me on the belay gadget.

“You’ve got a wireless remote control right on your harness, so you can let out more rope or pick up the slack with the press of a button,” she explains. “If you fall, a magnetic particle brake automatically stops the rope and holds you. There’s a fail-safe brake and manual clutch if anyone ever gets stuck.” Place it on the floor and the iClimb eliminates the need for a belaying partner—”at least in a gym,” she stipulates.

This spring, Blundo and her team plan to give demos to climbing-wall manufacturers for possible commercial development. Blair thinks it has definite promise, though he’s aware of the downside of innovation in a business world fixated on the bottom line. “It certainly works,” he tells me. “The big question in my mind is how the climbing gym’s liability insurance company will receive this. Are they more liable for an injury caused by a bad human belay or a faulty machine belay?”

FOR NOW, BLUNDO, like some of her fellow CSI gear mavens, can’t be bothered to worry about insurance company qualms. She’s already moved on to her next project: helping New Balance research an ultramarathon shoe. Meanwhile, Abel Hastings has yet to hear from New Balance, but still has his sights set on a sneaker revolution. And Marianne Okal—what of her inquiries into the mystery of carabiner destruction?

“It worked!!!” Blair e-mails me, referring to Okal’s experiments with the failure-detection mold. “We’ll want to reproduce the results, but this seems a viable solution.” Okal, he adds, is about to graduate and has made a list of where she’ll send her rĂ©e;sumĂ©e;: Black Diamond, Dynastar, MSR, Völkl, Salomon, and Petzl. But first she plans to do what any self-respecting, newly-minted grad of the MIT Center for Sports Innovation might do: ski Chamonix.